All About Beer

All About Beer – Grain To Glass

Fall is around the corner and that means the beginning of Beer Festivals in many parts of North-America and Europe. Not long ago, ordering a beer in a bar, or selecting one from the beer aisle was a simple task, you generally had only the choice of a few brands from large corporations. Today, we are witnessing a beer revolution as an ever growing number of small craft breweries offer innovative beers. What is the difference between a pale ale, brown ale, stout, and a lager? Or most basic, what’s the difference between an ale and a lager? Knowing the basics to define beers will allow you to more easily approach the choices, decide what aspects of beer give you the most enjoyment, and guide your customers in choosing the right beer.

INGREDIENTS

Barley Malt

The primary component of beer is the malt. It is barley or another grain that has been steeped in water, allowed to germinate for several days, and then dried out in a kiln. In the malting process, the starches found in the grains are converted to sugar. The malted grains also provide the protein and amino acids with the sugar that the yeast needs to carry out fermentation.

Hops

After malt, the most noticeable ingredient in beer is the hops. Hops are a critical component in offering a bitterness to balance the sweetness of the malt, in providing the aroma, and in acting as a natural preservative. As with malt, different varieties of hops are used in different regions and in different beers to create diverse effects.

Water

Water forms 85 to 95 percent of the finished beer. Many breweries have abandoned traditional wells and springs because of the threat of contamination. They used treated town water from the main supply and can add the minerals that they require.

Yeast

The combination of malt, hops, and water would be nothing more than that without the yeast. It is responsible for the fermentation as it consumes the sugars in the mixture to produce the by-products of alcohol and carbon dioxide (carbonation).

Other Additives

Although the four basic ingredients of malt, hops, water, and yeast are all that are needed to brew beer, many brewers choose to include other natural additives to their brews to influence the flavour, aroma, and colour, and thus create a unique product.

THE BREWING PROCESS

Malting

Malting

Malting is the process of partially germinating and roasting grain to be fermented. It provides the flavour and nearly all the colour of a beer.

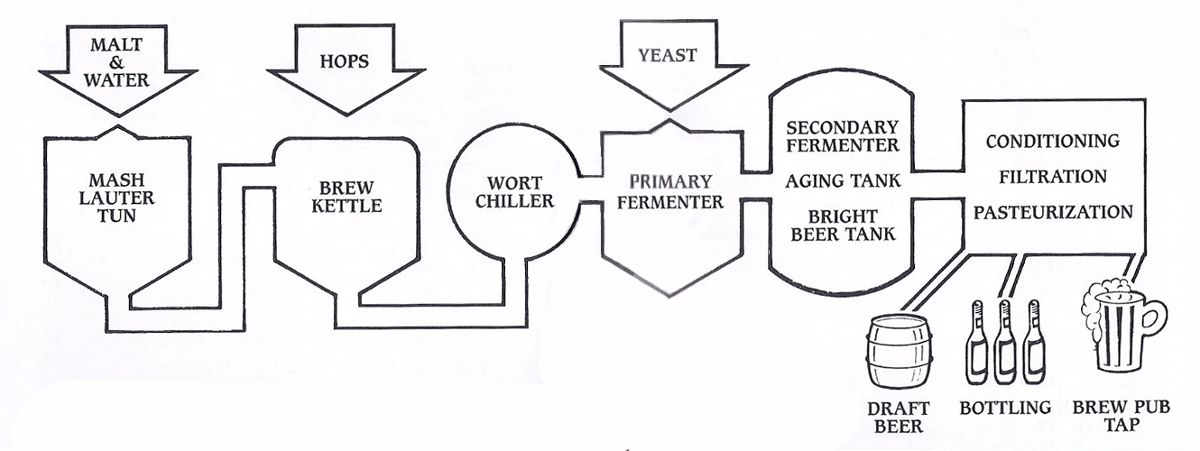

Mashing

The malt is crushed then mixed with water. Malt enzymes break down the starch to sugar. When mashing is finished, the mash is transferred to a brew kettle and hops are added.

Brewing

The liquid, called wort, is boiled to sterilize it and to extract the hops resins which contribute flavour, aroma and bitterness to the brew. Next, the hops are removed and the liquid is allowed to settle. The hot wort is strained and passed through a cooler to reduce temperature before it enters the fermenter.

Fermentation

At this point, the yeast is added to the wort. This causes fermentation which turns the sugar into alcohol and carbon dioxide. In lager beers, yeast settles to the bottom as a solid deposit. In ales, yeast rises to the top to form a creamy head.

Krausening

Krausening is a German method of adding carbon dioxide to beer by putting the brew through a second fermentation in a pressurized aging tank. It wakes up the dormant yeast floating in the beer and adds natural carbonation.

Aging

The fermented liquid ages from six weeks to three months depending of the beer style. Then the beer is filtered.

Pasteurizing

Certain beers are pasteurized (heated to high temperatures to kill bacteria) to increase shelf-life. Many craft breweries do not pasteurize their beers because they wish to retain the authentic beer flavours.

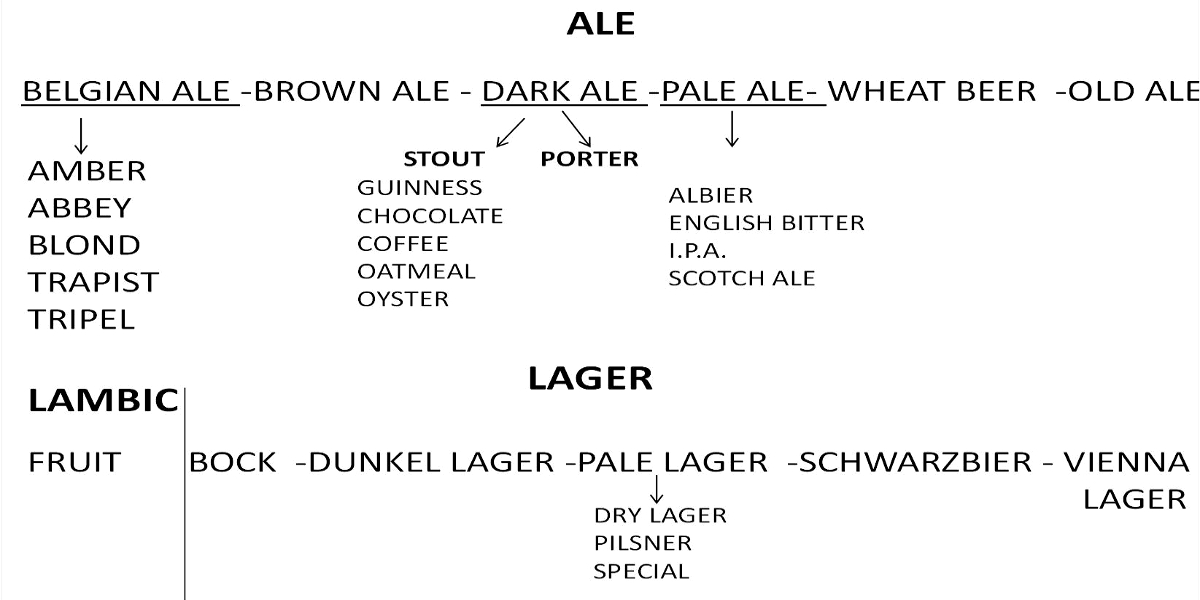

BEER FAMILY TREE

Cheers!