How Liqueurs Are Made?

How They Are Made

It is virtually impossible to describe exactly how liqueurs are created because of the wide variety of these drinks and the secrecy attached to their manufacturing. Although the possible combinations of ingredients are infinite, broad methods are used to produce a liqueur: a) infusion/maceration or percolation. b) spirit base. c) distillation. d) finishing.

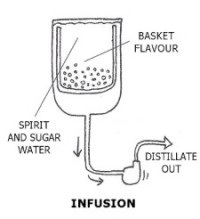

INFUSION/ MACERATION – The ingredients are crushed and left in cold water or in pure alcohol for weeks, months, or up to a year. The liquid is then strained off and added to neutral alcohol. Some brands will macerate different collections of ingredients in batches, while some will continue to add ingredients throughout the maceration process.

INFUSION/ MACERATION – The ingredients are crushed and left in cold water or in pure alcohol for weeks, months, or up to a year. The liquid is then strained off and added to neutral alcohol. Some brands will macerate different collections of ingredients in batches, while some will continue to add ingredients throughout the maceration process.

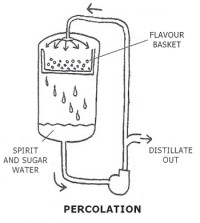

PERCOLATION – This method is laborious, but effective. The spirit is pumped from the bottom of a tank to the top (a device that looks like a coffee percolator), where it is sprayed over the ingredients enclosed in a basket. As the spirit percolate through the basket it absorbs the flavours of the ingredients, and the process can go on for weeks or months. In the end, the spirit-soaked flavourings is distilled to extract the last drop of flavour.

PERCOLATION – This method is laborious, but effective. The spirit is pumped from the bottom of a tank to the top (a device that looks like a coffee percolator), where it is sprayed over the ingredients enclosed in a basket. As the spirit percolate through the basket it absorbs the flavours of the ingredients, and the process can go on for weeks or months. In the end, the spirit-soaked flavourings is distilled to extract the last drop of flavour.

BASE SPIRIT- The base of any liqueur is some sort of neutral spirit made of molasses, grain, or grape. Some liqueurs rely on the flavour of a particular spirit. There are some distillers that use a flavoured aged spirit – for example, Grand Marnier uses Fine Champagne Cognac when assembling its blend.

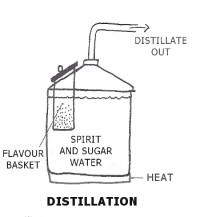

DISTILLATION – The product that results from infusion, maceration, or percolation methods is distilled. The bulk of the top liqueurs will use redistillation for all, or part of their product. Some distillers will keep their different batches of liquid separate, and distill them on their own before blending at a later stage, while others will combine them and redistill the whole lot.

DISTILLATION – The product that results from infusion, maceration, or percolation methods is distilled. The bulk of the top liqueurs will use redistillation for all, or part of their product. Some distillers will keep their different batches of liquid separate, and distill them on their own before blending at a later stage, while others will combine them and redistill the whole lot.

FINISHING – It’s common practice for the top brands to then age the finished product, usually this takes place in large used wooden vats which will mellow the liqueur and allow the flavours to marry. Alternatively, glass or stainless-steel tanks are also used. For some products, after the ageing process the liqueur is sweetened and adjusted for colour. Then the liqueur is filtered, cold stabilized and bottled.